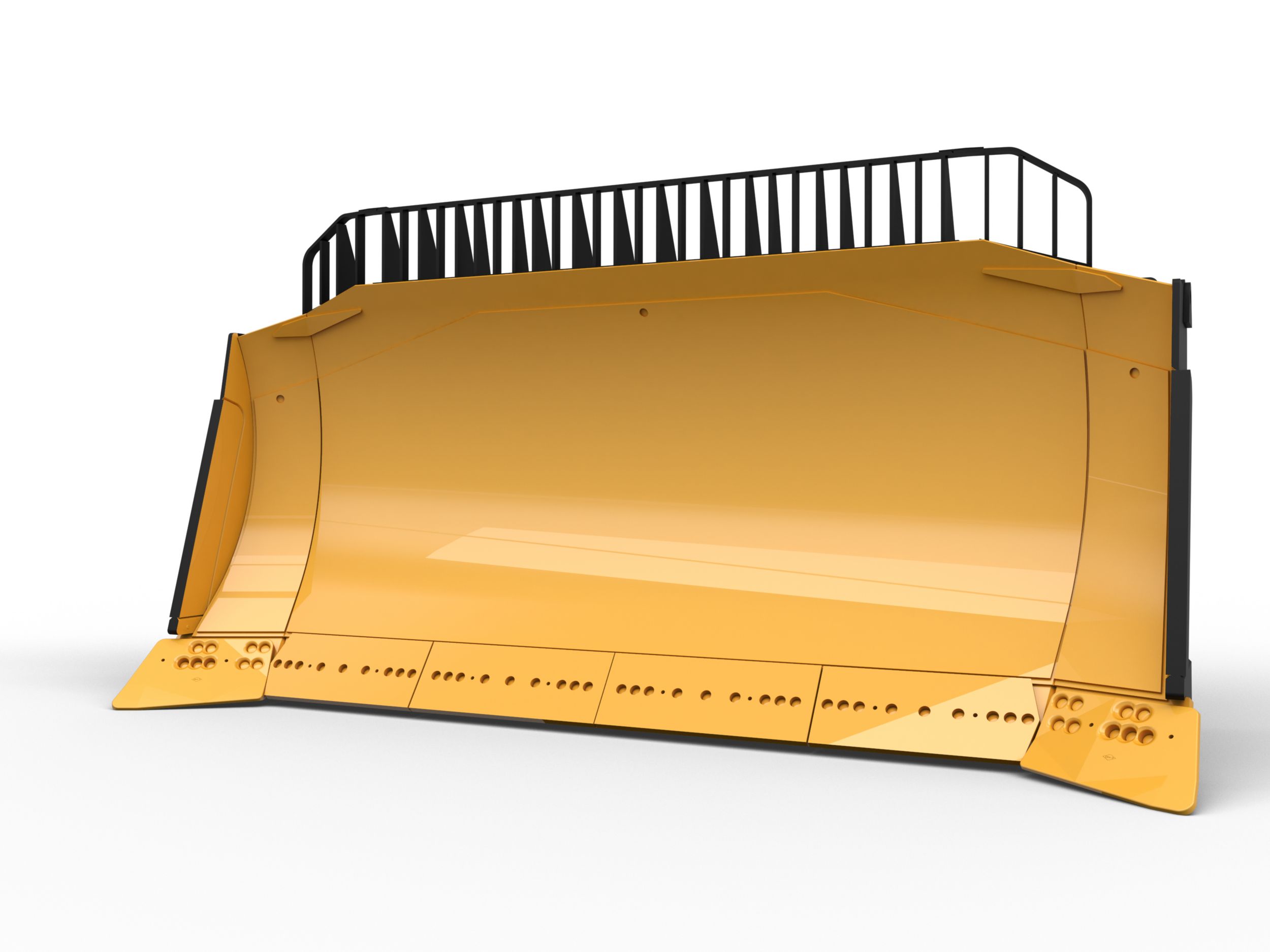

D11 Dozer

The new Cat® D11 Dozer delivers higher productivity at lower cost. The latest technology provides operator with full command of the dozer for safe and efficient operation. This means you can comfortably move more material in less time, at a lower cost per ton, for a faster payback on your investment. This intelligent dozer has a sophisticated machine protection strategy, as well as a machine guidance system which further drives higher productivity and lower cost.

| Engine Model | Cat® C32 |

|---|---|

| Engine Power - Net SAE J1349/ISO 9249 - Forward | 634 kW |

| Displacement | 32.1 l |

| Engine Power - Net SAE J1349/ISO 9249 - Reverse | 712 kW |

| Note (1) | *Excludes all fan losses. |

| Note (2) | Engine ratings apply at 1,800 rpm. |

| Note (3) | Net power advertised is the power available at the flywheel when the engine is equipped with air cleaner, muffler, alternator, fan, and engine emissions controls as required. |

| Operating Weight | 104236 kg |

|---|---|

| Operating Weight - Carrydozer | 113700 kg |

| Note (1) | D11 Operating Weight: Includes blade tilt cylinders, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 11U ABR bulldozer, single-shank ripper with pin-puller, fast fuel, 710 mm (28 in) ES shoes, and operator. |

| Note (2) | D11 CD Operating Weight: Includes lubricant, coolant, full fuel tank, 915 mm (36 in) extreme service shoes, 11 Carrydozer, singleshank ripper, and operator. |

| Semi-Universal (SU)* Capacity | 27.2 m³ |

|---|---|

| Semi-Universal (SU)* Width Over Endbits | 5584 mm |

| U-Blade Capacity | 34.4 m³ |

| U-Blade Width | 6340 mm |

| Reclamation Universal - Blade capacity (SAE J1265) | 42 m³ |

| Reclamation Universal - Width with blade (over end bits) | 6395 mm |

| Carry Dozer - Blade capacity (SAE J1265) | 43.6 m³ |

| Carry Dozer - Width with blade (over end bits) | 6704 mm |

| Width at Outside of Track (710 mm Track Shoe) | 3806 mm |

|---|---|

| Length with SU-Blade** - No rear attachment | 8765 mm |

| Overall Length SU-Blade and SS Ripper** | 10712 mm |

| Engine Model | Cat® C32 |

|---|---|

| Displacement | 32.1 l |

| Engine Power - Net SAE J1349/ISO 9249 - Forward | 634 kW |

| Engine Power - Net SAE J1349/ISO 9249 - Reverse | 714 kW |

| Note (1) | *Excludes all fan losses. |

| Note (2) | Engine ratings apply at 1,800 rpm. |

| Note (3) | Net power advertised is the power available at the flywheel when the engine is equipped with air cleaner, muffler, alternator, fan, and engine emissions controls as required. |

| Fuel Tank - Total Volume | 1895 l |

|---|---|

| Fuel Tank - Usable Volume | 1800 l |

| Pump Type | Variable displacement piston pump |

|---|---|

| Combined Pump Output - Implement | 670 l/min |

| Overall Beam Width | 3330 mm |

|---|---|

| Maximum Penetration Force - Shank Vertical | 344 kN |

| Maximum Penetration - Standard Tip | 1100 mm |

| Pry-Out Force - Multi-Shank Ripper with One Tooth | 648 kN |

| Maximum penetration force * (shank vertical) | 294 kN |

|---|---|

| Maximum penetration depth (standard tip) | 1612 mm |

| Pryout Force | 661 kN |

| Maximum penetration force * (shank vertical) | 294 kN |

|---|---|

| Maximum penetration depth (standard tip) | 2172 mm |

| Pryout Force | 661 kN |

| 1.0 Forward | 4 km/h |

|---|---|

| 2.0 Forward | 7 km/h |

| 3.0 Forward | 12.2 km/h |

| 1.0 Reverse | 4.8 km/h |

| 2.0 Reverse | 8.5 km/h |

| 3.0 Reverse | 14.7 km/h |

| Drawbar Pull - 1 Forward | 659.2 kN |

| Drawbar Pull - 2 Forward | 366.1 kN |

| Drawbar Pull - 3 Forward | 205.8 kN |

| Shoe Type | Extreme Service |

|---|---|

| Width - Shoe | 710 mm |

| Width - Shoe - CD | 915 mm |

| Shoes/Side | 41 |

| Grouser Height | 102 mm |

| Pitch | 318 mm |

| Ground Clearance* | 777 mm |

| Length - Track on Ground | 4444 mm |

| Ground Contact Area | 6.3 m² |

| Ground Contact Area - CD | 8.1 m² |

| Track Rollers/Side | 8 |

| Number of Carrier Rollers | 1 per side (optional) |

| Track Gauge | 2896 mm |

| Ground Clearance* | 798 mm |

|---|---|

| Track Gauge | 2896 mm |

| Width at Outside of Track (710 mm Track Shoe) | 3606 mm |

| Height (ROPS/canopy)* | 4723 mm |

| Length of Track on Ground | 4444 mm |

| Length with SU-Blade** - No rear attachment | 8579 mm |

| Overall Length SU-Blade and SS Ripper** | 10525 mm |

| Note | *Includes grouser height for total dimensions on hard surfaces. |

| ROPS | Rollover Protective Structure (ROPS) meets the following criteria: ISO 3471:2008 |

|---|---|

| FOPS | Falling Objects Protective Structure (FOPS) meets the following criteria: ISO 3449:2005 LEVEL II |

| Sound (1) | The exterior sound pressure level for the standard machine (ISO 6396:2008) is 116 dB(A) (sound suppressed). |

| Sound (2) | The operator equivalent sound pressure level (ISO 6396:2008) is 78 dB(A) (sound suppressed). |

| Cooling System Refill - Tier 2 Equivalent Engine | 158 l |

|---|---|

| Final Drive - Each | 47 l |

| Power Train | 454 l |

| Power Train - Refill Volume | 391 l |

| Roller Frames - Each | 94 l |

| Hydraulic System Tank and Chassis | 245 l |

| Hydraulic System Chassis + Blade and Ripper (Standard) | 445 l |

| Hydraulic System Chassis + Blade and Ripper (Carrydozer) | 540 l |

| Cooling System | 177 l |

| Engine Crankcase | 133 l |

| Hydraulic Tank | 160 l |

| Note (1) | The air conditioning system on this machine contains the flourinated greenhouse gas refrigerant R134a (Global Warning Potential = 1430). The system contains 2.1 kg (4.6 lb) of refrigerant which has a CO2 equivalent of 3.003 metric tonnes (3.31 tons) |

|---|

Ask Quotation

Usados